Industry Background

AL started out watching his Grandpa weld and fabricate from a young age. As he grew older, he took all industrial art classes available throughout high school. After graduating he worked at Neroco, starting out as an assembler and moving on to welding and fabricating. Simultaneously, attending NWTC for welding, fabricating, and metallurgy [the study of metal.] After graduating, he began working at Carver Yacht, where he started out as a welder, welding stainless, aluminum, and mild steel. AL worked his way up to prototype development of new boat models and eventually into management. After 26 years at Carver, he worked as a welder and fabricator for 5Point Fabrication and Richlen Enterprise and now is currently a project manager at Volm Companies.

Creative ToolBox

There are a few key elements that are essential for me to create my custom projects. I absolutely need my mig/tig welder, cutoff wheel, and grinder. Also, it is important for me to go through the proper planning and prep process to ensure the project creation phase is efficient and thorough. You can typically find me in the shop with the TV on or music playing and with the garage doors open to allow the breeze and creative vibes to flow. Last, I have learned how valuable it is for me to have my space and surrounding areas clean, this allows me to get into a rhythm and create a better turn out for the project!

Open to all Opportunities

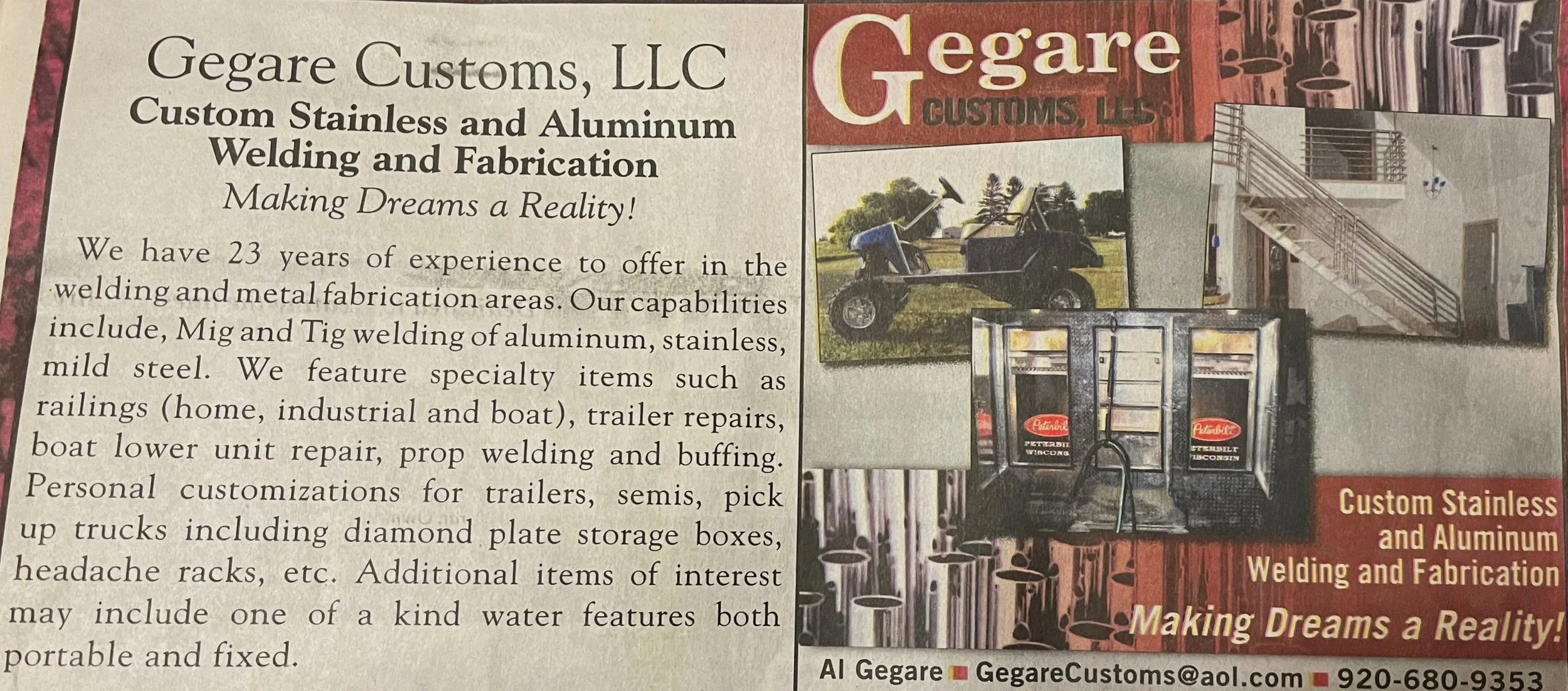

Building trailers and repairing anything that came AL’s way is what established Gegare Customs back in 2007. What began out of his house garage, has now grown through a few shops over the years. Focusing on marine repair, food-grade equipment, and now interior/exterior railings, while being open to all opportunities.

AL has the ability to create across a wide range of metals and project focuses. He enjoys the excitement and energetic thrill of seeing his clients happy with their final projects. As well as the satisfying feeling of working through the stages of each project; connecting with his clients, planning and preparing, creating, finishing, and installing.

AL enjoys thinking outside the box, is innovative, works with his customer to identify their exact needs, and fabricates the product at hand. He is self-sustained; owns all equipment in-house and has the ability to be mobile. With reliable suppliers of materials and finishings available as needed.

In his free time, you can find AL cruising the back roads in his hot rod with his wife Connie in the passenger seat, snowmobiling the trails from Wisconsin to Michigan, and enjoying the outdoors by chasing waterfalls or stoking up the next fire.

Featured In

Green Bay Press Gazette